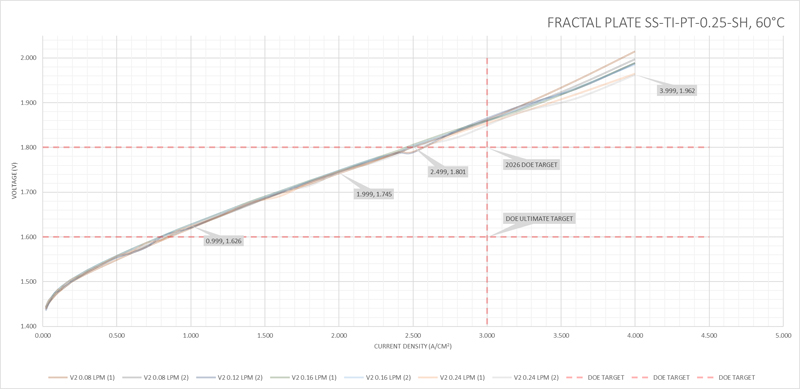

Forming and coating service of electrolyser bipolar plates. Tensor Technologies delivers precision-engineered PEM electrolyser bipolar plates with advanced coatings for unparalleled performance and durability. Our proprietary coating technology enhances corrosion resistance and conductivity, optimizing hydrogen production efficiency. Trust our expertise to elevate your electrolyser stack with cutting-edge, industry-leading solutions.

During the electrolysis process, a PEM electrolyzer bipolar plate is an essential part that helps separate the hydrogen and oxygen. The bipolar plate acts as a physical barrier between the anode and cathode as well as an electrical conductor. For these plates, coating services usually entail the application of a thin, resilient layer of materials such as titanium or platinum to improve conductivity, resistance to corrosion, and overall efficiency. The coating increases the electrolyzer's efficiency in creating high-purity hydrogen by guaranteeing long-term performance and dependability. Applications in industrial hydrogen production and renewable energy depend on this method.

PEM electrolyzer bipolar plates are critical components used in the electrolysis process to split water into hydrogen and oxygen. These plates serve as conductive pathways, facilitating the flow of electrons and ions within the electrolyzer. Coating services for these bipolar plates are essential to enhance their durability, conductivity, and resistance to corrosion. High-quality coatings ensure efficient performance, longevity, and reduced maintenance costs of the electrolyzer. By optimizing the functionality of bipolar plates, these services contribute significantly to the overall efficiency and cost-effectiveness of hydrogen production, supporting the advancement of clean energy technologies.