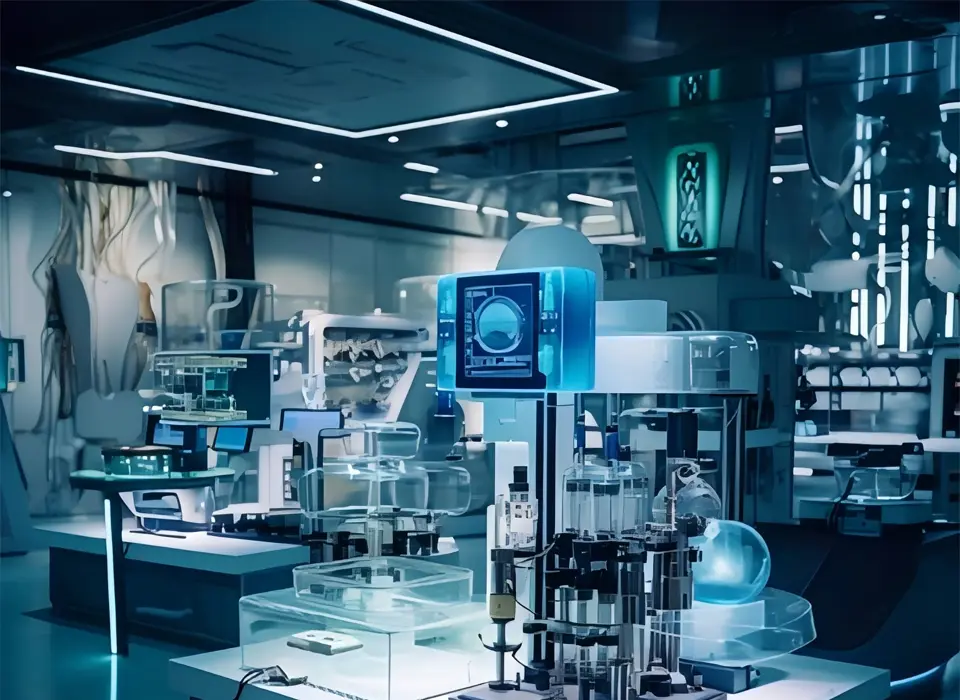

Tensor Technologies is dedicated to providing groundbreaking hydrogen energy technologies and setting the highest industry standards. Our test bench portfolio can support comprehensive testing and analysis of fuel cell and electrolysers. Designed and tailored by industry experts, the bipolar plates are equipped with durable coating, optimized fluid fields and affordable costs.

Forming and coating service of electrolyser bipolar plates.

Including GDL/PTL Tester and Testing Cell Hardware.

Simulate work condition of AEM electrolyser stack and conduct perfomance test, durability test and electrochemistry analysis of AEM cells/stacks.

Comprehensive test of fuel cell stacks and systems including electrochemistry test, sensitivity test, performance test and durability test.

Simulate work condition of PEM electrolyser stack and conduct perfomance test, durability test, production gas analysis and electrochemistry analysis of PEM cells/stacks.

Including Air tightness tester and Resistance detection equipment

A system for electrolyser usually includes water treatment and supply system, stack control system, AC/DC and DC/DC, heat rejection system and produced gas treament system. A test bench will have similar subsystems because its main function is to operate the electrolyser and acquire its performance data. The key differences which may lead to the need of a test bench are:

- Control Range of Work Conditions: Test benches are designed to operate electrolyser stacks on various and extreme conditions instead of a steady operation protocol to test the limits of the stack. The power, pressure and temperature controls on a test bench is usually having a larger control range and better resolution.

- Instrumentation: Test benches will usually have more types and intallation of instruments to fully diagonise the stack/cell, like gas analyzers, pressure transducers, electro-chemistry test stand, programmable power supplies. In most cases, same instruments also have better measurement accuracy on test benches.

- Software: Tensor test benchse are equipped with the powerful human-machine-interface (HMI) NOVA. It is a testing software with full functionality of parameters control, calibration, testing protocol scripting, alarm configuration and data logging and analysis. On a system, the control software is usally embedded in the circuit board CPU and the HMI is usually a touch screen or a communication cable to its upper control systems.

Performing EIS on Fuel Cells or Electrolyzer Cells

Experimental Setup:

Electrode Configuration: Usually, a three-electrode system is adopted, consisting of a working electrode (the fuel cell or electrolyzer cell sample), a counter electrode (commonly graphite or platinum), and a reference electrode (such as saturated calomel electrode or silver/silver chloride electrode).

Cell and Electrolyte: The electrodes are mounted in a suitable cell, and the cell is filled with the corresponding electrolyte solution. For example, in the case of a proton exchange membrane fuel cell, the electrolyte is usually a proton-conducting membrane and the appropriate aqueous solution.

Connection and Shielding: The electrodes are connected to the potentiostat's leads, and the entire setup is often placed in a Faraday cage to reduce noise interference.

Instrument Parameters Setting:

Frequency Range: The frequency range needs to be set according to the characteristics of the sample and the research purpose. Generally, it starts from a high frequency and sweeps to a low frequency. For example, in the study of fuel cells, frequencies in the kilohertz range are often used to determine high-frequency impedances such as membrane resistance, and low-frequency impedances can provide information about the electrochemical behavior of the fuel cell.

Amplitude of the AC Signal: A small amplitude alternating current signal is usually used to perturb the sample to ensure that the measurement is within the linear response range of the electrochemical system and does not cause significant changes in the sample's state.

Data Acquisition Points: Set an appropriate number of data acquisition points per decade of frequency to ensure the accuracy and resolution of the impedance spectrum.

Information Provided by EIS about the Sample

Ohmic Resistance: The real part of the impedance at high frequencies in the EIS spectrum mainly reflects the ohmic resistance of the sample, including the resistance of the electrolyte, electrodes, and other components in the fuel cell or electrolyzer cell. By analyzing the ohmic resistance, the conductivity and internal resistance of the sample can be evaluated, and the influence of factors such as material quality and assembly process on the internal resistance of the cell can be understood.

Polarization Resistance: The semicircle diameter in the Nyquist plot of the EIS spectrum is related to the polarization resistance, which reflects the resistance caused by electrochemical processes and diffusion in the sample. The magnitude of the polarization resistance can be used to evaluate the reaction kinetics and mass transfer characteristics of the electrode reaction in the fuel cell or electrolyzer cell, and to understand the activity and stability of the electrode.

Double Layer Capacitance: The imaginary part of the impedance in the EIS spectrum can provide information about the double layer capacitance at the electrode-electrolyte interface. The double layer capacitance is related to the surface area and electrochemical activity of the electrode, and can be used to study the adsorption and desorption behavior of reactants and products at the electrode surface, as well as the change of the electrode surface state.

Electrochemical Reaction Mechanism: By analyzing the shape and characteristics of the EIS spectrum at different frequencies, the electrochemical reaction mechanism in the fuel cell or electrolyzer cell can be inferred. For example, the impedance spectrum at different frequencies can be decomposed and analyzed by methods such as the distribution of relaxation time to understand the specific processes and reaction rates of charge transfer, mass transfer, and chemical reaction in the electrochemical system.

Performance and Stability Evaluation: EIS can be used to monitor the performance and stability of fuel cells or electrolyzer cells. By comparing the EIS spectra of the sample under different working conditions or at different times, the changes in the internal impedance and electrochemical properties of the sample can be observed, and the performance degradation and stability problems of the cell can be evaluated and predicted.